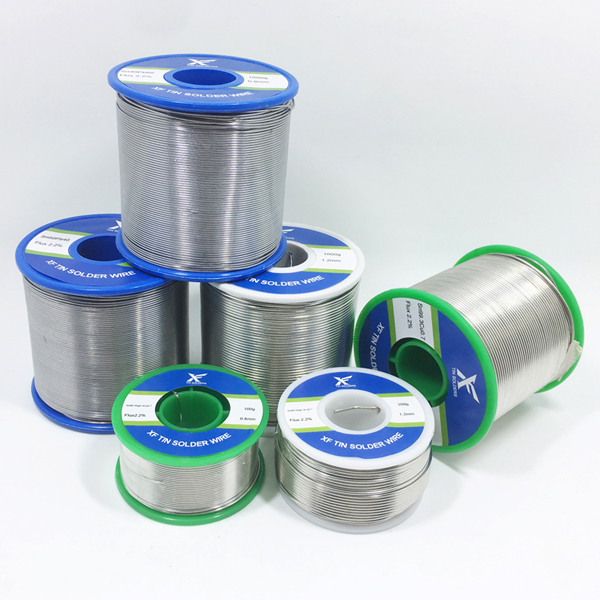

| Name: | Lead Solder Wire 63/37 Sn63Pb37 250g for Electronics from China |

Product Description

Lead Solder Wire 63/37 Sn63Pb37 250g for Electronics

When it comes to soldering electronic components, choosing the right solder wire is crucial for ensuring strong, reliable connections. Among the various options available, lead solder wire 63/37 Sn63Pb37 stands out as a top choice for professionals and hobbyists alike. In this article, we will explore the technical aspects, benefits, and best practices for using lead solder wire for electronics, specifically the lead solder wire 63/37 250g variant.

What Is Lead Solder Wire 63/37 Sn63Pb37?

Lead solder wire 63/37 refers to a solder alloy composed of 63% tin (Sn) and 37% lead (Pb). This specific ratio is known as the eutectic mixture, meaning it has the lowest melting point (183°C or 361°F) of any tin-lead combination. The lead solder wire Sn63/Pb37 formulation ensures a smooth transition from solid to liquid state, minimizing the risk of cold solder joints.

The lead solder wire Sn63/Pb37 for electronics is widely used in PCB assembly, wiring, and component soldering due to its excellent wetting properties and mechanical strength. The lead solder wire 63/37 250g package is a convenient size for both small repairs and larger projects.

Why Choose Lead Solder Wire 63/37 for Electronics?

1. Eutectic Properties for Reliable Soldering

Unlike non-eutectic solders that have a plastic range (where the alloy is partially melted), lead solder wire 63/37 Sn63Pb37 transitions directly from solid to liquid at a single temperature. This property reduces the risk of disturbed joints, making it ideal for precision work in electronics.

2. Excellent Wetting and Flow Characteristics

The lead solder wire Sn63/Pb37 provides superior wetting, ensuring that the solder spreads evenly over the joint. This results in strong electrical conductivity and mechanical stability, critical for circuit board reliability.

3. Lower Melting Point for Safer Operation

With a melting point of 183°C, the lead solder wire 63/37 for electronics requires less heat compared to higher-temperature solders, reducing thermal stress on sensitive components.

4. Strong and Durable Joints

The lead solder wire Sn63/Pb37 250g produces joints with excellent tensile strength, making it suitable for applications where mechanical stress is a concern.

How to Use Lead Solder Wire 63/37 Sn63Pb37

1. Preparing the Soldering Iron

Set your soldering iron to 250–300°C (482–572°F) for optimal performance with lead solder wire 63/37.

Ensure the tip is clean and properly tinned to improve heat transfer.

2. Cleaning the Work Surface

Remove oxidation or debris from the PCB pads and component leads using isopropyl alcohol or a fiberglass pen.

Proper cleaning ensures better adhesion of the lead solder wire Sn63/Pb37 for electronics.

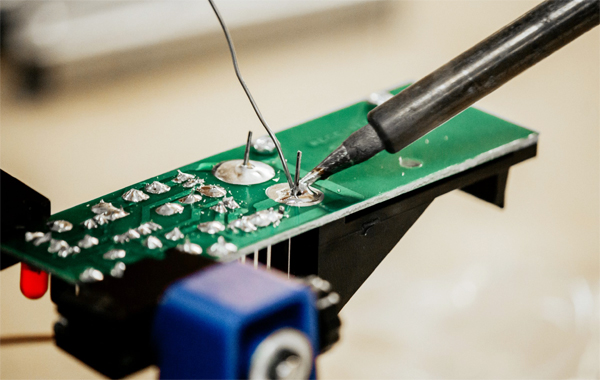

3. Applying the Solder

Touch the soldering iron tip to both the component lead and the PCB pad simultaneously.

Feed the lead solder wire 63/37 250g into the joint until it melts and flows smoothly.

Avoid excessive solder, which can cause bridging between connections.

4. Inspecting the Joint

A well-soldered joint using lead solder wire Sn63/Pb37 should appear shiny and concave, indicating proper wetting. Dull or grainy joints may indicate cold soldering and should be reworked.

Safety Considerations When Using Lead Solder Wire

While lead solder wire for electronics offers superior performance, lead exposure can be hazardous. Follow these safety tips:

Work in a well-ventilated area to avoid inhaling fumes.

Wash hands thoroughly after handling lead solder wire 63/37 Sn63Pb37.

Consider using a fume extractor when soldering for extended periods.

Comparing Lead Solder Wire 63/37 with Other Alloys

Lead Solder Wire vs. Lead-Free Solder

Lead solder wire Sn63/Pb37 melts at a lower temperature than lead-free alternatives (which typically require 217–227°C).

Lead-free solders (e.g., SAC305) are more brittle and can form weaker joints compared to lead solder wire 63/37 for electronics.

63/37 vs. 60/40 Solder

While lead solder wire 63/37 is eutectic, 60/40 solder has a slight plastic range, making it more prone to joint defects if moved during cooling.

The lead solder wire Sn63/Pb37 250g is preferred for precision work where consistency is key.

Conclusion

For anyone working in electronics assembly or repair, lead solder wire 63/37 Sn63Pb37 remains a top-tier choice due to its eutectic properties, ease of use, and reliability. The lead solder wire Sn63/Pb37 for electronics ensures strong, conductive joints with minimal risk of defects. Whether you're a professional technician or a DIY enthusiast, the lead solder wire 63/37 250g package provides an excellent balance of performance and convenience.

By following proper soldering techniques and safety precautions, you can maximize the benefits of lead solder wire for electronics and achieve flawless soldering results every time.

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997